Top Load Tester

Top Load Tester Manufacturers

Easily maintain compliance with industry standards with The Bharat Group’s Top Load Tester Manufacturers in Faridabad. More companies than ever are committed to preserving the environment by minimizing packaging and increasing its recyclable content. Innovation in new materials and packaging layouts is making a significant contribution to lightening and sustainability projects, but it is crucial that they do so without sacrificing a container's overall performance or robustness. Top-load testing becomes a crucial tool for executing quality control in that situation.

Top-load testing, also referred to as column-crush, vertical load resistance, and axial force resistance, involves compressing a packaging container downward and determining how much it is resistant to deforming. Choosing our Top Load Tester in Haryana would be a great choice as you will enjoy some offers and discounts during the purchase.

- Our Top Load Tester can be customized to fit your unique testing needs, giving you the flexibility to optimize your materials and processes.

- Investing in our Top Load Tester is a smart business decision that can save you time and money.

- We use high-quality materials to construct our Top Load Tester, making it built to last and capable of withstanding the demands of any industrial environment.

For precise and trustworthy testing, rely on our Top Load Tester exporters and suppliers in India. We prioritize customer satisfaction in everything we do. So don't just watch virtually, make it to your doorstep before it gets out of stock.

About Top Load Tester

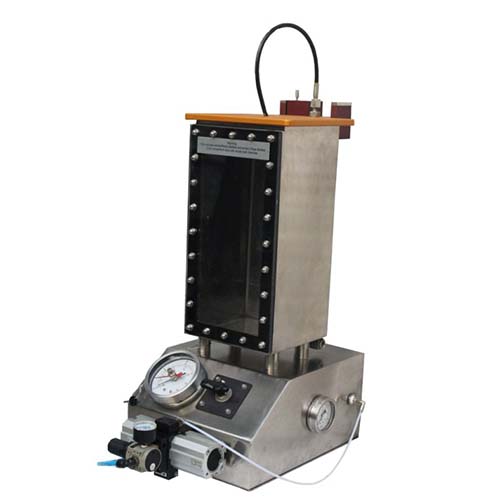

“TBG” Top Load Tester is used for measuring vertical strength of bottle. Good strength avoids damage of bottles during stacking, Transportation, Storage and packing. Bottle Compression Tester is efficient and easy to use equipment intended for measuring the ability of bottle to resist external compressive forces. This method describes how to determine the resistance of a bottle to compressive forces. This is accomplished by placing the bottle between two flat platens, one of which is mechanically driven to compress the bottle. A recording device is incorporated to indicate the force required to compress the bottle. The method is used to compare the compressive resistance of different lots of similar bottles or to compare bottles of different grades.

The instrument is made in two parts, one is for main instrument and the other is the control panel. The ultimate test is to determining overall quality and performance of the bottles and jars. The instrument is bright chrome plating, zinc plating, painted in metallic paints. It is supplied complied with electrical which include micro-switches, Push buttons and contactors for safe and convenient operation.

In Computerized model, we provide the Window based software which gives the different measurement parameter and the graph. The report can be printout by using proper printer. The variable speed model speed is vary by a knob fixed on the panel and the speed also digitally indicated on the control panel of the instrument or by simply types the speed on the monitor of the computer. Different model have speeds suitable for testing different materials. Various built in safety arrangements such as over travel protection, are provided.

THE BHARAT GROUP, TBG, Opposite Radha Swami Satsang Damdama Road Bhogpur, CRPF, Pinjore, Haryana 134104